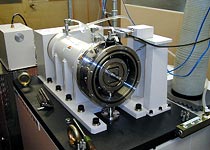

Máy kiểm tra ma sát và mài mòn

Model : EFM-III Series

Hãng sản xuất : AND

| Features of the EFM-III Series |

- Conforms with JIS K 7218

- Applicable to ring, disc and pin test pieces

- Sliding speed ranging from 0.001 cm/sec to 1000 cm/sec

- Frictional force measurement ranging from 2 N-cm to 1000 N-cm

- System can be customized (additional measurement and control items, etc.) |

|

| EFM-III Series applications |

- Evaluation of friction properties relating to materials and products (metal, plastic, ceramics, bearing materials, brake lining

materials, clutch disks, self-lubricated materials, lubricant oil, etc.)

Measurement of static/kinetic friction Measurement of static/kinetic friction

Measurement of wear amount Measurement of wear amount

Measurement of PV limit value Measurement of PV limit value

Evaluation of seizure conditions Evaluation of seizure conditions

- Evaluation of the friction properties according to material combinations

- Evaluation of the relation between surface treatment and friction properties

- Evaluation of the relation between environmental conditions and friction properties

Examples of tests in conformity with JIS K 7128 |

|

| Ring- on-ring |

Ring-on-disc |

Three-pin-on-disc |

|

|

| Measurement and control system |

Add-on software MSAT0009

- Enables automatic control of the tester's contact pressure and sliding velocity in incremental steps (up to 50 steps)

- Displays a graph detailing average values of friction coefficient, etc. at each step

- Saves test data as well as easily retrieves and displays test results

- Displays each calculation item in various units |

|

|

| MSAT0001 |

MSAT0009 |

|

|

| Customizable system using the AD-5400 series |

- By using the AD-5400 series or the AD-4820 series, a measurement and control system can be built to meet the needs of customers.

- Devices for adding measurement items:

AD4820 optional board

AD5430-01 16ch A/D board

- Devices for adding control items

AD5430-11 Six-axis encoder input board to control motor

AD4820-10 Standard I/O board to control heater, etc.

- Signal conditioner

It is possible to design and manufacture a signal conditioner to connect to the AD-5400 series or the AD-4820 series, which makes it possible to respond to the additional measurement and control needs of customers. |

|

|

|

|

|

|

| General purpose testing machine data processing system |

General purpose testing machine data processing system

Add-on software MSAT-0009 for the friction and wear tester

This additional data processing software controls the revolution speed and the contact load of the EFM series and other various friction and wear testers and can acquire and analyze friction data. |

| Setting |

Measurement |

Reference |

|

|

|

| Preset conditions to automatically perform stepwise control of contact load (pressure load P) and revolution speed (sliding velocity V) are required for friction test evaluation to collect data. |

Friction force, contact load, revolution speed and temperature data can be acquired and then converted into various units to be displayed in a graph or table. Results can be output in an arbitrary combination of friction coefficient, contact pressure, sliding distance, sliding velocity, etc. |

Data on the relation between PV value and friction coefficient can be displayed based on the step average of the measurement result. |

|

|

| Specifications |

Basic software MSAT-0001

Add-on software for friction and wear tester MSAT-0009

Automatic pressurizing mechanism |

| Control item |

- Maximum number of STEPS: 100

(holding time of each step can be selected from seconds, minutes or hours*)

- Contact load: 5000N at maximum

- Revolution speed: limited value of the tester |

| Measurement item |

Contact load, Contact pressure

Friction force, Friction force amplitude, Friction force, Maximum friction force, Minimum friction force

Elapsed time

Revolution speed

Sample temperature

Ambient temperature

Amount of friction

Sliding distance

Coefficient of friction, Amplitude of friction coefficient, Maximum friction coefficient, Minimum friction coefficient

PV value

Optional equation |

|

|

| Data unit of measurement |

| Physical quantity |

Unit |

| Contact pressure |

Pa, kPa, MPa, GPa, N/mm2, N/cm2, gf/mm2, gf/cm2, kgf/mm2, kgf/cm2, tf/mm2, tf/cm2, pai, dyn/cm2 |

| PV value |

Pa・m/sec, kPa・m/sec, MPa・m/sec, GPa・m/sec, gf/mm2・m/sec, kgf/mm2・m/sec, tf/mm2・m/sec, gf/cm2・m/sec, kgf/cm2・m/sec, tf/cm2・m/sec, psi・in/sec |

| Time |

s, min, h, ms, µs |

| Coefficient of friction |

Dimensionless |

| Amount of friction |

µm, mm, cm, m, in, ft, km |

| Sectional area |

µm2, mm2, cm2, m2, in2, ft2 |

| Revolution speed (angular speed) |

rpm, rad/s |

| Temperature |

°C, K, °F |

| Velocity |

mm/min, mm/sec, m/min, m/sec, in/sec |

| Load |

mN, cN, N, gf, kgf, lbf, dyn |

| Mass |

g, kg, lb |

|

|

| Sample result using the general purpose testing machine data processing system |

|

Specifications Specifications |

|

| Test piece and mounting attachment |

1. Ring-on-ring test piece

|

2. Attachment for ring-on-disc

|

3.Attachment for three-pin-on-disc (optional)

|

1. Ring-on-ring test piece

1. Cylindrical test piece

2. Cylindrical test piece for temperature measurement

(Option with thermocouple hole)

2. Attachment for ring-on-disc

1. Flat plate test piece (hard material)(optional)

Height: 30 mmLength: 30 mmWidth: 2 mm -5 mm

2. Disk test piece (optional)

Diameter: φ46 mmWidth: 2mm - 5 mm

3.Attachment for three-pin-on-disc (optional)

1. PinDiameter: φ5 mmHeight: 8 mmNumber of pins: 3

2. DiskDiameter: φ60 mm |

|

|

| Option |

| 1. Test piece and mounting attachment |

(a)Metal cylindrical test piece for temperature measurement (S45C)

(b)Mounting attachment for cylindrical test piece

(c)Mounting attachment for flat plate test piece

(d)Attachment for pin-on-disc |

| 2. Oil bath |

Capacity: approx. 250 cc

Maximum sliding velocity: 200 cm/sec |

| 3. Heating oil bus |

Capacity: approx. 800 cc

Maximum sliding velocity: 200 cm/sec

Temperature control range: Rt – +100°C

Temperature controller: PID temperature control |

| 4. Simplified heating furnace |

Temperature range: Rt – +300°C

Temperature controller: Slidax

Temperature setting: 3-digit digital method |

| 5. High temperature chamber |

Heating method: Circulating hot air

Temperature range: Rt – +200°C

Temperature distribution: ±5°C (30 at center, 10 mm at top and bottom) |

| 6. High and low temperature chamber |

Cooling method: Liquid carbon dioxide spray

Heating method: Circulating hot air

Temperature range: -50 – +200°C

Temperature distribution: ±5°C(φ30 at center, 10 mm at top and bottom)

Liquid CO2 usage: 30 kg cylinder for 24 hours |

| 7. Pseudo-friction measurement instrument |

Measurement range: 0 – 5 mm

Resolution: 0.1% FS

Linearity: 1.0 % FS |

|

|

|

|

| High and low temperature chamber |

Oil bath |

|

|

| A wide variety of friction and wear testers |

|

Compact friction and wear tester table model

(Pin-on-disc test) |

|

Rolling friction and wear tester

[Lubricating material, Oil, Bearing material] |

|

Reciprocating friction and wear testing instrument

[Painted surface, Characteristic evaluation of coating material] |

|

|

|

| Main unit |

Controller |

|

|

High-speed/high-pressure friction and wear tester

Maximum revolution speed: 1100cm/sec

Maximum contact load: 2.5KN |

|

|

| Main unit |

Controller |

|

|

For EFM series friction and wear tester

[Pressure measurement instrument] |

|

|

|

| AD-5430 series |

Bearing friction and wear tester |

|

|